|

When it comes to learning what works and what doesn’t, nothing beats experience. Today however, we have YouTube! Here are some short and sweet videos that explain what happens when band saw blades are misapplied.

1 Comment

VSM STEARATE Plus fibre disc XF733 optimizes the grinding process for demanding NF metals and aluminium. Reduced chip adhesion and hence less clogging result in double the amount of stock removal and double the service life.

This has been demonstrated through numerous tests performed for a variety of applications at the VSM Technical Centre in Hanover. STEARATE Plus significantly reduces chip adhesion "NF metals such as aluminium, bronze and copper are very demanding materials, which tend to clog the abrasive prematurely", states Dennis Senning, VSM Product Manager. When that happens, chips are not removed. They accumulate on the grain tips and after some time, a built-up edge is formed.

Doubling the service life Field tests demonstrated that XF733 has double the service life compared to the currently leading abrasive when grinding aluminium superstructures for the automotive industry. Similar results of an increase in the service life were achieved when grinding window frames. And XF733 scored high in another area: The temperature in the contact area is usually extremely high. Backing materials of other products tend to warp and blister. The vulcanized fibre backing of the VSM STEARATE Plus disc, on the other hand, is extremely heat-resistant and remains fully efficient until it reaches the end of its service life. This chart is based on punching mild steel with a 65, 000 lb. shear strength. All information in this chart should be verified before applying it to your work particularly when using combinations that approach the machine’s maximum tonnage capacity. Buy a Slugger by FEIN mag drills and get a cutter set, cutting fluid, and cutting paste for FREE! Offer good only on sales of Slugger by FEIN mag drills during the stated promotional period ending December 31. 20202. There is No limit on rebate quantities! For multiple tool purchases, please indicate quantity ordered. This offer is only good in the USA. The Accessories will automatically be shipped with new orders. Standard Workstations & Features An Ironworker is a class of machines that can shear, notch, and punch holes in steel plate. The name is now used to refer an entire class of machines. If there ever was a brand name, it's become a genericized trademark. Ironworkers generate force using mechanical advantage or hydraulic systems. Modern systems use hydraulic rams powered by a heavy AC electric motor. High strength carbon steel blades and dies of various shapes are used to work the metal. The machine itself is made of very heavy steel to handle the enormous force that can be generated during use. The Amada Marvel Spartan Series Ironworkers are rated according to the force they can generate in tons; ratings usually start at 60 tons and go as high as 192 tons. A typical ironworker from Amada Marvel will have:

PUNCHING The double acting punch cylinder is machined and faced to assure proper alignment of the cylinder shaft under maximum load. Cylinder stroke length is adjustable both top and bottom with two easily set limit switches. The see-through stripper provides full view of punch for ease of alignment and operation. The stripper is also adjustable for varying thickness of material.

The various machines punch from 1/8" to 2" in diameter. Punching from 2-1/16" to 4" is achievable with usage of the oversize attachment feature. Punches and dies are easily interchangeable. Both round and shaped tools can be used in the machine. BAR SHEARING STATION The round and square bar station allows for shearing various sizes. T-bar and channel shear blades are also available for this station With the bar shearing feature, rounds and squares can be cut from 1/8" to 2-1/8" (Larger sized holes are available on larger machines only). By changing the blades you can also cut T-bars, H-beams, and channel iron. FLAT BAR SHEAR The flat bar shear station has a cast iron support table with guides for accurate positioning and has scribe marks at 90 and 45 degrees for miter cuts. With the adjustable holddown and an upper blade with only a 3 degree rake angle, deformation is held to a minimum. The lower blade has four useable sides. A special feature of the flat bar shear is its variable degree miter-cutting on the bottom leg of the angle iron PLATE SHEAR Complete daily flat bar shearing with flat and precise results, complimented by the unique anti-distortion blade.. ANGLE SHEAR The angle shear allows for both straight and miter cuts of varying sizes of angle material without a drop-out slug. The two wear guides assure the squareness of every cut, while the adjustable holdown keeps distortion to a minimum. The angle shearing feature allows the option to cut angle iron at 90 degrees, and smaller angle iron at 45 degrees. This feature can be done with both the top and bottom leg. NOTCHING The notcher is ideal for notching on either flat bars or angles. The gauging table has adjustable stops for precise positioning and the safety guard is electrically interlocked for maximum safety and visibility. Notching needs are met with a rectangular notching tool, standard on each machine. Marvel can provide special notching tools for a variety of desired applications. *Punching diameter, material diameter and thickness can change according to machine models Optional Accessories LARGE HOLE AND SECTION PUNCHING, BENDING ATTACHMENT

The above video discusses some of the newest Ironworker features:

The Kalamazoo Machine Tool model C370 A-NC EXT cold saw is a fully automatic, heavy-duty vertical column machine engineered for vibration-free sawing. The 48-in. index feeder enables production of longer workpieces without having to stop and reset indices. The saw features infinitely variable blade speed control from 13 to 89 RPM to enable fine-tuning for precise sawing of difficult materials. The saw frame can be swiveled for mitering to any desired angle up to 45 degrees left or 60 degrees right. The pendant-mounted NC console has soft-touch controls for all setup and sawing operations, including height/depth controls. The C370A-NC is a rugged, heavy-duty vertical column circular sawing machine. The vertical column constructions provides extremely stable saw frame guidance and stability with vibration free sawing!

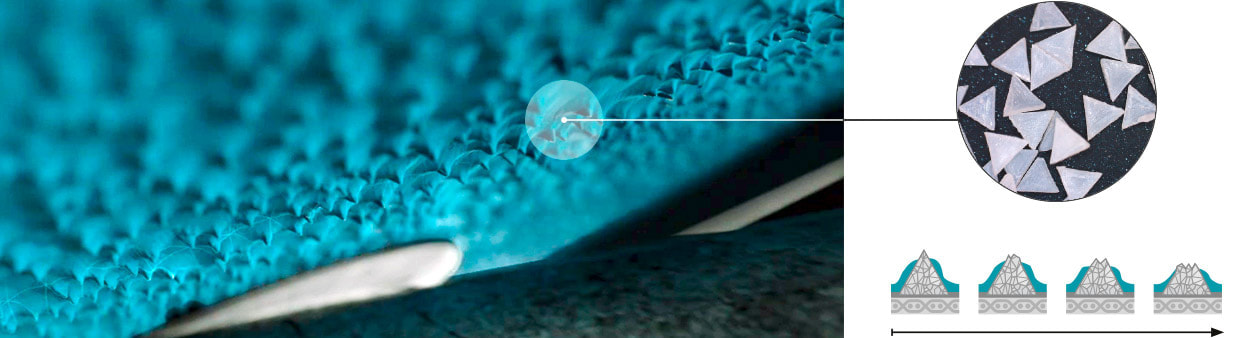

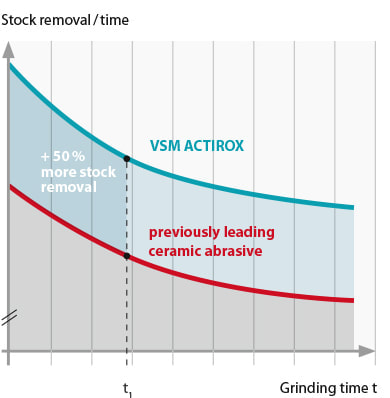

Infinitely variable blade speeds offer flexibility to fine tune the settings for sawing even the most difficult materials. The operators control is one of the easiest to use programmable saw control on the market. Stores frequent jobs for fast recall. VSM ACTIROX is the latest generation of abrasives. It stands for maximum stock removal. Thanks to its geometrically shaped ceramic grain its cut is extremely aggressive and fast, leading to maximum stock removal. This works particularly well with alloyed steel, stainless steel and carbon steel. An impressive increase in productivity can be achieved using the abrasive in conjunction with the new back-up pad VSM TURBO PAD. VSM ACTIROX - The latest generation of abrasives for maximum stock removal. The abrasive for faster cut and an increase in productivity thanks to geometrically shaped ceramic grain.

Robert Röntgen is one of the world’s leading manufacturers of saw bands and saw blades for metal cutting.

Due to the variety of its band saw blades, Röntgen is able to cover a wide range of applications including Square tubes, Angles, Plate, Square tubes in bundles, Bundled angles, Small round solids, Wall and floor tiles, Graphite/Carbon, Sandwich panel, Foundry cutting among many other uses. Palmgren is part of the family of brands of the C. H. Hanson Company. C. H. Hanson is one the nation’s oldest manufacturers and has been family-run for five generations. C.H. Hanson’s family of brands, Hanson, Hansco-Mark, Palmgren and Norse, offer a wide range of high-quality products that are used every day across a broad range of industries. C.H. Hanson has a rich history of truly building “Tools for Generations.” Starting now and through 2020, Palmgren is having Special Machinery Sales Event! Below you can find a promotions catalog that you can download to get all of the details on the metalcutting, fabrication and woodworking equipment this is part of this promotion!

Amada Marvel, Inc. (AMV), located in Oshkosh, WI and Amada Machinery America, Inc. (AMCA), located in Schaumburg, IL and Los Angeles, CA continue to integrate as part of the merger completed in July of 2018. Company efforts have been re-aligned by restructuring roles for each respective Amada Company. Effective on 4/01/2020, AMCA controls the functions of all sales and service activity in North America. Therefore, please direct all machine, part, service and blade orders to the following new AMCA email addresses and phone numbers:

AMV will be responsible for the Manufacturing of a variety of AMCA and global product offerings sold through AMCA.

This unified effort will allow for both the Amada and Amada Marvel product offerings to improve and focus on even better customer support. The reputation developed through quality product offerings along with the support to follow is critical for continued success. AMCA and AMV realize this and will continue with this focus in mind. |

NEWS

The latest products, news, information, tech tips and industry updates. Archives

March 2021

Categories

All

|

|

Corporate Offices & Showroom

1508 9th Avenue Longview, WA 98632 |

|

© 2023 Douglas Clay & Associates Inc. All Rights Reserved

|

site design: Rapid Production Marketing

|

RSS Feed

RSS Feed