|

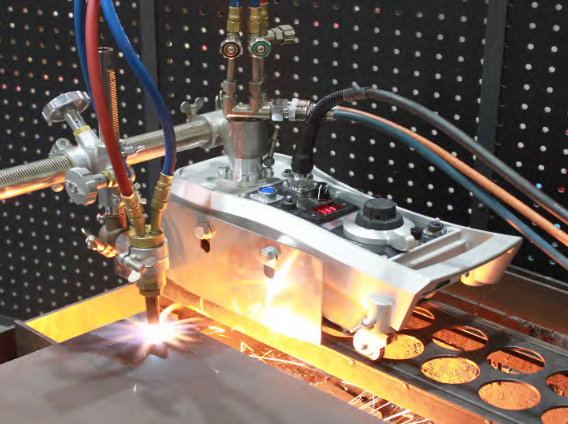

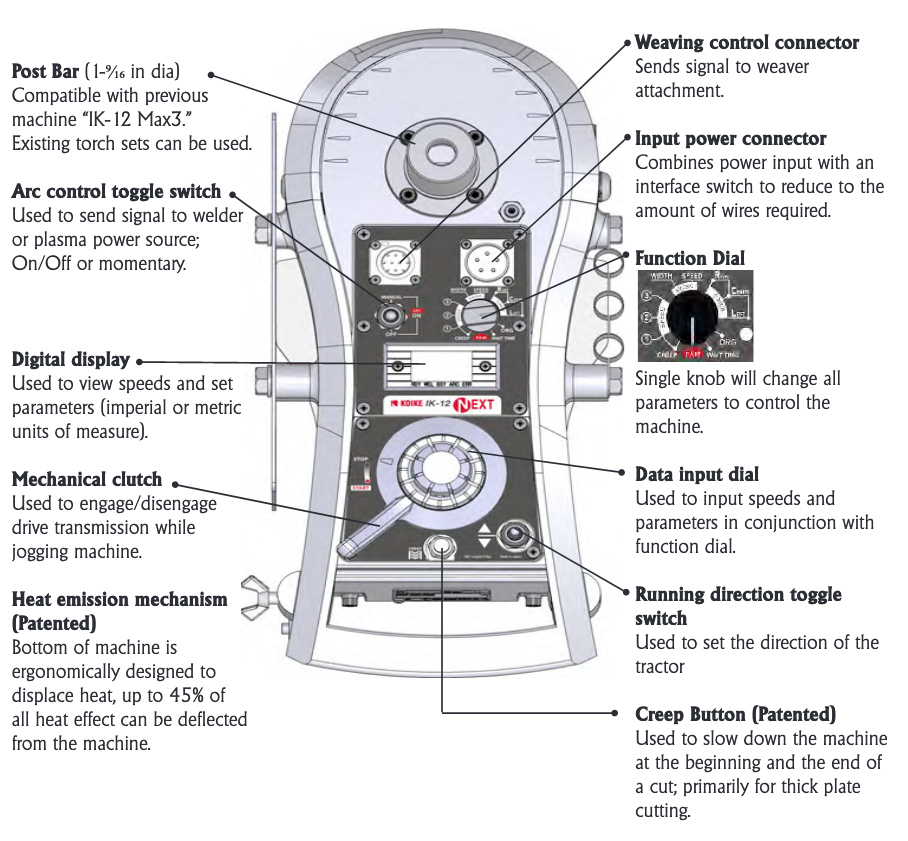

Arcade, NY – Koike Aronson announced its newest iteration of the highly acclaimed IK-12 automation carriage. IK-12 NEXT is the latest model of the IK series, one of the most popular and longest selling gas cutting carriages in the fabrication industry. Designed to replace the rugged IK-12 Max3, one of the most popular and longest selling cutting carriages in the fabrication industry. The IK-12 NEXT is an incredibly strong, versatile tractor that is specifically designed to be compatible with most applications. With the ability to adapt to each process, the machine is versatile but still retains a simplistic operating system With a new control panel and body redesign, it offers even greater versatility with the ability to cut and weld with the same carriage. This is complimented by a plethora of different cutting and welding head attachments.

The newly patented “CREEP MODE” enables the user to instantly switch to low speed mode at the start and finish of each run. This helps with heat transfer commonly found with working thicker plate. With the optional weaving attachment, larger welds can be produced in a single pass, thus greatly increasing productivity. “With the IK-12 NEXT, we set out to offer even more flexibility, while retaining the ease-of-use the IK-12 is known for,” said McMahon. “You can opt for single or multiple torch configurations, as well as perform an extensive amount of work with the same carriage. The IK-12 is essentially the Swiss army knife of portable cutting and welding.”

“The user interface on the IK-12 NEXT makes it extremely simple to learn,” said Ron Krasnek, Manager of Global Sales and Marketing. “You can set speed presets and monitor your settings on the digital display, but using intuitive analog controls. It’s the best of both worlds, because it’s sophisticated and versatile, but also easy to use.”

0 Comments

|

NEWS

The latest products, news, information, tech tips and industry updates. Archives

March 2021

Categories

All

|

|

Corporate Offices & Showroom

1508 9th Avenue Longview, WA 98632 |

|

© 2023 Douglas Clay & Associates Inc. All Rights Reserved

|

site design: Rapid Production Marketing

|

RSS Feed

RSS Feed